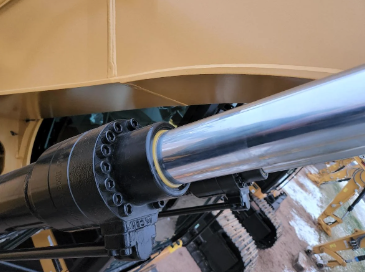

Telescopic Hydraulic Cylinders

HDM is considered the industry leader in small-bore telescopic cylinders. We custom design our single-acting and double-acting telescopic cylinders to meet the requirements of your application.

For additional weight savings, we can offer telescopic cylinders with aluminum bodies and steel stages.

Our depth and breadth of experience allow us to understand your challenges and design the optimal solution for a range of equipment, including agricultural equipment, construction equipment, dump trucks, refuse trucks, and transfer trailers.

Telescopic hydraulic cylinders are a type of hydraulic actuator that consists of multiple nested cylinders, allowing for a significant extension of the overall length when deployed. This design enables the cylinders to achieve a long stroke while maintaining a compact retracted size, making telescopic hydraulic cylinders ideal for applications with space constraints.

Each cylinder section is called a “stage,” and as hydraulic fluid is pumped into the cylinder, each stage extends sequentially, resulting in a powerful lifting or pushing action. Their ability to provide high force and versatile motion makes them essential in numerous hydraulic systems where efficiency and compactness are crucial.

Key markets in which telescopic hydraulic cylinders are used include:

Key Markets:

- Agriculture

- Construction

- Manufacturing

- Material Handling

- Mining

- Transportation

- Waste Management

Key Applications:

- Dump Trucks

- Refuse and GarbageTrucks

- Construction Equipment

- Material Handling

- Agricultural Machinery

- Aerial Work Platforms (AWPs)

- Mining and Drilling

Smooth Operation

Light Weight

Anodized Treated

Less Corrosive

than Steel

General Features & Specifications

Key features and specifications include:

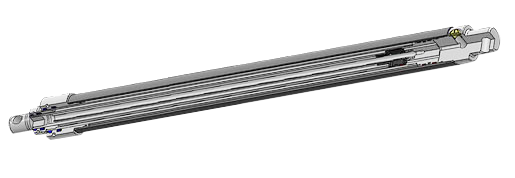

- Multi-Stage Structure. Consists of multiple nested tubes (or stages) that extend sequentially. The number of stages typically ranges from two to six, which allows for greater stroke lengths compared to standard cylinders.

- High Stroke-to-Retracted Length Ratio. Provides long strokes that are often several times the retracted length. This feature makes telescopic hydraulic cylinders ideal for applications where space constraints are a concern and high extension is required.

- Compact Design. Can fit into tight spaces, offering versatility for machines that have limited room for larger, conventional cylinders.

- Varied Bore and Stroke Sizes. Allows for use in applications ranging from light-duty lifting to heavy industrial operations.

- Single-acting or Double-acting Operation. Has the versatility to accommodate hydraulic pressure applied in both directions for extending and retracting the cylinder.

- High Load Capacity. Designed to handle heavy loads, making them suitable for lifting, pushing, or supporting large amounts of weight, especially in heavy machinery such as dump trucks, cranes, and material handling equipment.

- Sealing and Wear Protection. Equipped with robust sealing systems to prevent hydraulic fluid leaks and protect against external contamination such as dust and dirt, extending cylinder life by minimizing wear on moving parts.

Custom Telescopic Hydraulic Cylinders

Custom options for telescopic hydraulic cylinders can include:

- Bore sizes

- Stroke length

- Number of Stages

- Material

- Mounting Configurations

- Sealing Systems

Hydraulic Cylinder Resources

Frequently Asked Questions

Have a question about Telescopic Hydraulic Cylinders? We are here to help.

What is a telescopic hydraulic cylinder?

A telescopic hydraulic cylinder is a specialized hydraulic cylinder that extends in multiple stages, allowing for a much longer stroke than its initial retracted length, making it ideal for applications with limited space but requiring significant extension.

How many stages can a telescopic cylinder have?

Telescopic cylinders can have anywhere from 2 to 6 stages, depending on the application. The number of stages increases the stroke length but also affects the complexity and strength of the cylinder.

What is the difference between single-acting and double-acting telescopic cylinders?

Single-acting telescopic cylinders use hydraulic pressure to extend and rely on gravity or external forces to retract, whereas double-acting telescopic cylinders use hydraulic pressure for both extension and retraction.

What are common applications for telescopic hydraulic cylinders?

Common applications include dump trucks, refuse trucks, construction equipment, aerial work platforms, material handling equipment, agricultural machinery, and mining equipment where high stroke-to-retracted length is required.

What materials are used in the construction of telescopic cylinders?

Telescopic cylinders are typically constructed from high-strength steel for durability, but custom options may include materials like stainless steel or special coatings for corrosion resistance in harsh environments.

Can telescopic cylinders be customized?

Yes, telescopic cylinders can be customized in terms of stroke length, number of stages, bore size, mounting options, sealing systems, and materials to meet the specific requirements of an application.

What is the maintenance requirement for telescopic hydraulic cylinders?

Regular maintenance includes inspecting seals for leaks, checking hydraulic fluid levels, monitoring for wear or damage, and keeping the cylinder clean from dirt and debris that could impact performance.

What are the common causes of failure in telescopic cylinders?

Common causes of failure include seal wear and tear, hydraulic fluid contamination, overloading beyond design capacity, corrosion, and inadequate maintenance leading to internal damage.

What is the maximum stroke length for a telescopic cylinder?

The maximum stroke length can vary significantly depending on the design, but telescopic cylinders can often achieve strokes of several meters, with some large industrial models reaching up to 10 meters or more.

How do you size a telescopic hydraulic cylinder for an application?

Sizing involves calculating the required stroke length, load capacity, available retracted length, and system pressure. Consulting with a hydraulic engineer or manufacturer is typically recommended to ensure the correct sizing.

Can telescopic cylinders be used in high-temperature environments?

Yes, telescopic cylinders can be designed for high-temperature environments by using specialized materials, heat-resistant seals, and proper fluid selection to ensure consistent performance under extreme conditions.

What is the typical lifespan of a telescopic hydraulic cylinder?

The lifespan varies depending on usage, maintenance, and environmental factors, but with proper care, a telescopic cylinder can last for many years. Frequent inspection and preventive maintenance significantly extend their life.

How does a telescopic cylinder extend and retract?

Answer: A telescopic cylinder extends by sequentially pressurizing the stages, pushing out each stage in turn. Retraction occurs either by reverse hydraulic pressure (in double-acting models) or by an external force like gravity (in single-acting models).

Are telescopic hydraulic cylinders available for purchase off-the-shelf?

Yes, standard telescopic hydraulic cylinders are available off-the-shelf, but many applications require custom cylinders tailored to specific needs, particularly in industries like construction, agriculture, and waste management.

What factors affect the cost of a telescopic hydraulic cylinder?

The cost depends on factors such as the number of stages, bore size, stroke length, materials used, customization options, and any special coatings or seals required for extreme conditions.

Contact Us

To learn more about how our innovative hydraulic cylinders are made with premium coatings and materials can deliver outstanding performance in highly corrosive environments, provide longer cylinders life, and decrease your maintenance costs, tell us who you are and briefly describe your application.

When you use HDM’s field-proven cylinders, you’re getting products and systems that are reliable, rugged and high-performance.