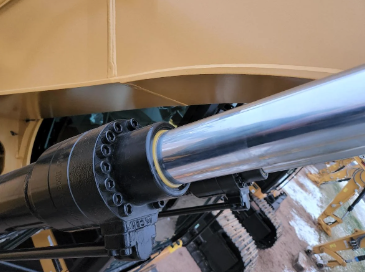

Rephase Hydraulic Cylinders

Our rephase hydraulic cylinders are designed to synchronize the extension and retraction of two or more cylinders. Custom rephrase cylinders are designed to meet the specific requirements of our customers' applications.

If your application could benefit from, maximum control over complex hydraulic systems, increased stability, improved load distribution, no mechanical connections between actuators, and no devices or plumbing for hydraulic resynchronization, we have custom and standard solutions that can add value to your operations.

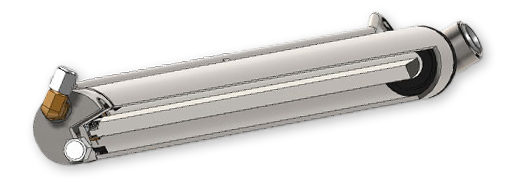

Rephase hydraulic cylinders are specialized types of hydraulic cylinders designed to synchronize multiple cylinders in a hydraulic system. They ensure that all cylinders in a series extend or retract uniformly, even when they are of different sizes or are exposed to unequal loads. This coordination is achieved through internal passageways that allow fluid to flow between cylinders, automatically balancing pressure and fluid distribution.

Some key features include integrated rephasing ports for fluid transfer, robust construction for durability, and the ability to work in both single- and double-acting systems. The benefits of rephasing cylinders are their ability to ensure smooth and consistent operation, particularly in applications that require multiple synchronized movements, as in agricultural or construction equipment. This feature reduces wear and tear on machinery, enhances control, and improves system reliability by preventing cylinder misalignment or uneven extension.

Key Markets:

- Agriculture

- Construction

- Mining

- Forestry

- Material

- Oil & Gas Drilling

- Waste Management

Key Applications:

- Agricultural Planting Equipment

- Boom Lifts and Cranes

- Road Graders

- Log Loaders

- Drilling Rigs

- Snowplows

- Waste Compactors

Synchronized Motion

Load Holding

General Features & Specifications

- Rephasing Ports. These built-in internal passageways or ports allow fluid to transfer between cylinders, ensuring synchronized movement.

- High-Pressure Ratings. Typically designed to withstand high hydraulic pressures (e.g., 3000-5000 PSI), enabling the cylinders to handle heavy loads.

- Double- or Single-Acting Design. Available in both double-acting (powered both ways) and single-acting designs, depending on application requirements.

- Custom Stroke Lengths. Can be manufactured with custom stroke lengths tailored to specific applications.

- Durable Construction. Made from aluminum, or from high-strength materials such as alloy steel or ductile iron, to help ensure longevity and resistance to wear and tear.

- Corrosion Resistance. Often coated with corrosion-resistant materials or finishes to enhance performance in harsh environments, such as agriculture or construction.

Custom Rephase Hydraulic Cylinders

- Specialized stroke lengths

- Port configurations

- Bore sizes

- Custom mounting styles

- Wear-resistant materials

- Corrosion-resistant coatings

- Temperature-resistant seals

Hydraulic Cylinder Resources

Frequently Asked Questions

Have a question about Rephase Hydraulic Cylinders? We are here to help.

What is a rephase hydraulic cylinder?

A rephase hydraulic cylinder is a cylinder with internal fluid passageways that allow for the synchronization of multiple cylinders in a hydraulic system, ensuring uniform extension and retraction even under varying loads.

How do rephase cylinders work?

Rephase cylinders work by using built-in rephasing ports or passageways that allow hydraulic fluid to flow between cylinders in a series, automatically balancing pressure and fluid levels to maintain synchronized movement.

In what applications are rephase cylinders most commonly used?

Rephase cylinders are commonly used in agricultural machinery, construction equipment, forestry equipment, road graders, and drilling rigs where synchronized motion of multiple cylinders is critical.

What are the key benefits of using rephase hydraulic cylinders?

Key benefits include synchronized cylinder movement, improved control, reduced wear on machinery, enhanced performance in systems with multiple cylinders, and overall increased reliability of hydraulic operations.

Can rephase hydraulic cylinders be customized?

Yes, rephasing cylinders can be customized with options such as custom stroke lengths, bore sizes, mounting configurations, corrosion-resistant coatings, and temperature-resistant seals.

What types of hydraulic systems are compatible with rephase cylinders?

Rephase hydraulic cylinders can be used in both single-acting and double-acting hydraulic systems, depending on the specific application requirements.

What is the maximum pressure rating for most rephase cylinders?

Most rephase hydraulic cylinders are rated for pressures between 3000 to 5000 PSI, although this can vary based on custom designs and application needs.

Do rephase cylinders require special maintenance?

Rephase cylinders do not require special maintenance beyond regular hydraulic cylinder care, such as checking for leaks, ensuring proper fluid levels, and inspecting seals for wear.

How do rephase cylinders improve machine performance?

By ensuring synchronized movement of multiple cylinders, rephase cylinders prevent misalignment, reduce uneven wear, and ensure smooth operation, leading to improved machine efficiency and reliability.

What are common signs that a rephase cylinder needs to be repaired?

Common signs include slow or uneven cylinder movement, leaks from seals or ports, reduced load capacity, and abnormal noises during operation.

Are rephase hydraulic cylinders suitable for harsh environments?

Yes, rephase cylinders can be designed with corrosion-resistant coatings and seals that withstand extreme temperatures, making them suitable for harsh environments such as agriculture, mining, and construction.

What are rephase ports, and why are they important?

Rephasing ports are internal fluid passageways within the cylinder that allow hydraulic fluid to transfer between cylinders, ensuring uniform motion and synchronized operation in multi-cylinder systems.

Can rephase cylinders be retrofitted into existing systems?

Yes, rephase cylinders can often be retrofitted into existing hydraulic systems, although proper sizing, pressure matching, and system adjustments may be required.

What materials are rephase hydraulic cylinders typically made from?

Rephase hydraulic cylinders are commonly made from high-strength materials like alloy steel or ductile iron for durability, with options for wear-resistant and corrosion-resistant coatings.

What industries benefit the most from rephase cylinders?

Industries like agriculture, construction, mining, forestry, material handling, and waste management benefit the most from rephasing cylinders due to their need for synchronized and precise hydraulic movements.

Contact Us

To learn more about how our innovative hydraulic cylinders are made with premium coatings and materials can deliver outstanding performance in highly corrosive environments, provide longer cylinders life, and decrease your maintenance costs, tell us who you are and briefly describe your application.

When you use HDM’s field-proven cylinders, you’re getting products and systems that are reliable, rugged and high-performance.