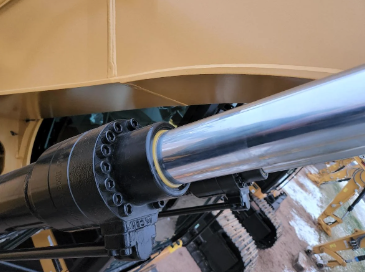

Ram Cylinders

Ram hydraulic cylinders are designed to provide high-force linear motion using hydraulic fluid pressure.

Unlike traditional hydraulic cylinders, which have a piston and rod arrangement, ram cylinders typically feature a single rod that acts as both the piston and the extension mechanism. These cylinders are generally used in applications where a large amount of force is required over relatively short distances, such as in jacks, presses, or snow plow equipment.

The primary function of a ram cylinder is to convert hydraulic energy into mechanical force, enabling it to lift, push, or hold heavy loads with precision. Because of their design, ram cylinders are highly effective for tasks requiring direct and concentrated force. This feature makes them essential in industries like construction, mining, and manufacturing, where heavy loads must be moved or stabilized with equipment that is reliable and powerful.

The importance of ram cylinders lies in their ability to handle high pressure and deliver significant force while safely helping to maintain control of equipment in demanding applications. These benefits make them invaluable in operations where mechanical advantage and controlled power are critical for efficiency and safety.

Key Markets:

- Agriculture

- Automotive

- Construction

- Manufacturing

- Mining

- Oil and Gas

- Snow and Ice Control

Key Applications:

- Dump Truck Beds

- Snow Plows

- Hydraulic Brakes

- Hydraulic Elevators

- Hydraulic Jacks

- Industrial Presses

- Lifting Equipment

Smooth Operation

Light Weight

Anodized Treated

Less Corrosive

than Steel

General Features & Specifications

- Heavy-Duty Materials such as high-strength steel or alloy, to withstand high pressures and harsh operating environments.

- High Force Output to handle heavy loads, often providing immense force with limited stroke lengths.

- High Pressure Ratings that allow them to operate at pressures ranging from 3,000 to 5,000 PSI or more, depending on the application.

- Mounting Options with various configurations, such as flange, trunnion, or clevis, to fit specific equipment setups.

- Shorter Stroke Lengths compared to other hydraulic cylinders, because their designs require that feature.

- Simple Construction that includes a single rod acting as both the piston and the extension mechanism for durability and efficiency.

Custom Ram Cylinders

Custom ram cylinders can be tailored to specific applications by modifying factors like stroke length, pressure capacity, rod diameter, and material composition. Customization options also extend to mounting configurations, seals, and coatings, allowing the cylinder to be optimized for unique environmental conditions and operational demands.

Custom options include:

- Material Selection

- Mounting Configuration

- Pressure Rating

- Rod Diameter

- Seal Types & Protective Coatings

- Stroke Length

- Bore Sizes

Frequently Asked Questions

Have a question about Ram Hydraulic Cylinders? We are here to help

What is a ram cylinder, and how does it differ from other hydraulic cylinders?

A ram cylinder is a type of hydraulic cylinder designed for high-force applications with a single rod that acts as both the piston and extension mechanism. Unlike standard hydraulic cylinders with separate pistons and rods, ram cylinders are optimized for delivering powerful linear motion over shorter distances.

In what industries are ram cylinders most used?

Ram cylinders are widely used in industries like construction, mining, manufacturing, agriculture, automotive, and oil and gas, where heavy loads must be lifted, pushed, or moved.

What types of forces can a ram cylinder generate?

Ram cylinders can generate substantial forces, often ranging from several tons to hundreds of tons, depending on their size, bore diameter, and the hydraulic pressure applied.

What are the typical stroke lengths available for ram cylinders?

Stroke lengths for ram cylinders vary depending on the application but are typically shorter than those of traditional hydraulic cylinders, often ranging from a few inches to a few feet.

How do I determine the correct bore and rod size for my application?

The correct bore and rod size depend on the load requirements, pressure rating, and desired force output. Consulting with a hydraulic expert and considering the application's operating conditions is essential to selecting the appropriate dimensions.

What materials are commonly used in the construction of ram cylinders?

Ram cylinders are often constructed from high-strength materials like carbon steel, stainless steel, or alloy steel to withstand high pressures and harsh environments. Specialized coatings or treatments may also be used to enhance durability and resistance to corrosion.

How can ram cylinders be customized for specific applications?

Ram cylinders can be customized by altering stroke length, bore size, rod diameter, pressure capacity, and material choice. Additionally, mounting options, seals, and coatings can be tailored to specific operational conditions, such as high temperatures or corrosive environments.

What is the maximum pressure rating for a standard ram cylinder?

The maximum pressure rating for ram cylinders typically ranges between 3,000 and 5,000 PSI, though custom cylinders can be designed to handle higher pressures based on application needs.

What maintenance is required to ensure the long-term performance of ram cylinders?

Regular maintenance includes checking for leaks, inspecting seals and rods for wear, ensuring proper lubrication, and keeping the hydraulic system free of contaminants. Periodic inspections and timely repairs help maintain performance and prevent failure.

Can ram cylinders be used in extreme environments, such as high temperatures or corrosive conditions?

Yes, ram cylinders can be designed for extreme environments by selecting appropriate materials, seals, and coatings. For instance, stainless steel or special alloys can resist corrosion, while high-temperature seals can be used in hot environments. Customization allows the cylinder to perform reliably in challenging conditions.

Contact Us

To learn more about how our innovative hydraulic cylinders are made with premium coatings and materials can deliver outstanding performance in highly corrosive environments, provide longer cylinders life, and decrease your maintenance costs, tell us who you are and briefly describe your application.

When you use HDM’s field-proven cylinders, you’re getting products and systems that are reliable, rugged and high-performance.