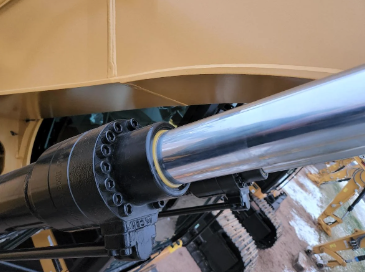

Piggyback Hydraulic Cylinders

When a longer stroke than a single cylinder can provide is needed, a piggyback cylinder is an ideal alternative.

Our piggyback hydraulic cylinders are designed to accommodate applications that have limited space while requiring additional strokes as well as consistent extension and retraction speeds. The piggyback configuration allows for more compact machinery while still delivering the necessary force and range of motion.

A piggyback cylinder consists of two cylinders mounted end-to-end (back-to-back) in a parallel configuration. The rods of both cylinders extend and retract together, effectively doubling the stroke capacity without requiring a longer single cylinder, which could be impractical or space-prohibitive.

Each cylinder of the piggyback design can have either the same or different size bores to accommodate the application. Using same size bores eliminates “staging” that may be an issue with typical telescopic cylinders.

Additionally, this setup can enhance stability and distribute forces more evenly, reducing wear and tear on the equipment. Piggyback cylinders are commonly used in heavy-duty applications where high performance, durability, and extended reach are crucial. We manufacture these cylinders in custom and standard configurations. Our designs result from a breadth and depth of engineering expertise that allow us to meet the requirements of customers in a range of industries.

Key Markets:

- Construction

- Industrial

- Snow & Ice Control

- Transportation

- Turf Care

Key Applications:

- Automobile Carriers

- Brakes

- Construction Equipment

- Cranes

- Deck Lifts

- Forklifts

- Industrial Presses

- Jibs

- Liftgates

- Plow Lifts

- Steers

- Truck Loaders

Smooth Operation

Light Weight

Compact Design

Hot & Cold Temperature

Range

General Features & Specifications

Key features of our Piggyback Hydraulic Cylinders include:

- Piggyback Design. Features two hydraulic cylinders mounted in tandem to achieve longer strokes while minimizing the overall length of the cylinder assembly.

- Compact Size. Designed to save space by using a piggyback configuration, reducing the length of the cylinder while providing extended stroke capabilities.

- High-Pressure Capability. These cylinders can operate under high pressure, often rated for pressures up to 3,000 PSI or more, depending on your specific requirements.

- Versatility. Suitable for various industrial and mobile applications, including material handling, lifting equipment, and other applications requiring compact design and extended strokes.

- Durability and Performance. Precision manufacturing ensures reliable performance with features like low friction seals, honed tubing for smooth operation, and high-strength materials for longer service life.

Custom Piggyback Hydraulic Cylinders

Piggyback hydraulic cylinders have many features that can be customized to a user’s specifications. We apply our engineering and manufacturing expertise to develop cylinders that are best for your specific application including:

- Material Choice

- Mounting Configurations

- Seal Types and Materials

- Port Configuration and Sizes

- Cylinder Bore and Rod Sizes

- Special Coatings and Finishes

Hydraulic Cylinder Resources

To help you understand piggyback hydraulic cylinders as deeply as you would like, we have created and compiled useful resources, including:

Frequently Asked Questions

Have a question about Piggyback Hydraulic Cylinders? We are here to help.

What is a piggyback hydraulic cylinder?

A piggyback hydraulic cylinder is a dual-cylinder configuration where two cylinders are mounted in parallel and connected at their rods. This allows for double the stroke of a single cylinder without requiring more space.

What are the main advantages of using a piggyback hydraulic cylinder?

The primary advantage is the ability to achieve long strokes in limited space. This design minimizes overall cylinder length while doubling the cylinder stroke.

In which applications are piggyback hydraulic cylinders commonly used?

They are typically used in applications requiring long strokes but limited installation space, such as mobile equipment, material handling, construction machinery, and industrial presses.

How does a piggyback hydraulic cylinder work?

In a piggyback cylinder, both cylinders extend and retract simultaneously, as they share the same hydraulic fluid circuit. The configuration results in a combined extended stroke while keeping the cylinders’ retracted length short.

What are the limitations of piggyback hydraulic cylinders?

Piggyback hydraulic cylinders may experience more complex alignment issues, increased weight, and can be more difficult to maintain due to the parallel cylinder arrangement.

How does a piggyback hydraulic cylinder compare to a telescopic hydraulic cylinder?

A telescopic cylinder uses nested tubes to achieve long strokes with a compact retracted length, while a piggyback cylinder uses two cylinders side by side to achieve a long stroke. Telescopic cylinders are typically more expensive and used in applications like dump trucks, whereas piggyback cylinders are simpler and suitable for moderate to long strokes in various applications.

What factors should be considered when selecting a piggyback hydraulic cylinder?

Consider factors like stroke length, mounting configuration, load capacity, operating pressure, cylinder alignment requirements, and space constraints.

Are piggyback hydraulic cylinders difficult to maintain?

Maintenance can be more complex than standard single cylinders due to the dual-cylinder setup. However, with proper alignment and periodic checks, they can be kept in good working order.

Can piggyback hydraulic cylinders be customized?

Yes, piggyback cylinders can be custom-made to meet specific stroke, mounting, and application needs. Manufacturers can tailor the cylinder size, bore, rod diameter, and other features to fit unique requirements.

How does the synchronization between the two cylinders in a piggyback setup work?

The two cylinders are connected hydraulically, meaning that the fluid entering one cylinder simultaneously moves into the other, ensuring that both cylinders extend and retract at the same time.

What are some common issues with piggyback hydraulic cylinders?

Common issues include misalignment, unequal wear of cylinder rods, and difficulty in maintaining the parallel connection. These issues can cause leakage, wear, and performance degradation over time.

What is the typical stroke length that can be achieved with a piggyback hydraulic cylinder?

Stroke lengths can vary, but typically range from a few feet to several feet, depending on the cylinder size and configuration. The advantage of a piggyback design is that it doubles the effective stroke compared to a single cylinder of the same length.

How do you install a piggyback hydraulic cylinder?

Installation involves securing the cylinders in a parallel configuration with proper alignment. Mounting brackets, pins, and rod ends should be aligned to prevent binding during operation.

What are the space-saving benefits of a piggyback hydraulic cylinder?

By splitting the stroke between two cylinders, the overall length of the cylinder assembly when retracted is much shorter compared to a single cylinder with the same stroke. This makes it ideal for space-constrained environments.

What kind of maintenance schedule is recommended for piggyback hydraulic cylinders?

Regular maintenance includes checking for leaks, monitoring rod wear, ensuring proper alignment, and verifying the hydraulic fluid condition. Regular inspections should be carried out depending on the application’s operational intensity.

Contact Us

To learn more about how our innovative hydraulic cylinders are made with premium coatings and materials can deliver outstanding performance in highly corrosive environments, provide longer cylinders life, and decrease your maintenance costs, tell us who you are and briefly describe your application.

When you use HDM’s field-proven cylinders, you’re getting products and systems that are reliable, rugged and high-performance.