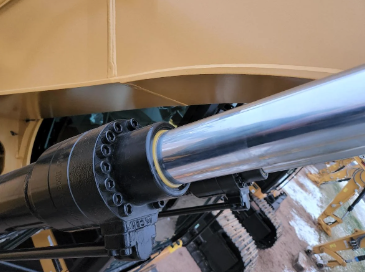

Linear Feedback Hydraulic Cylinders

Linear feedback devices can be internally or externally mounted to provide precise hydraulic cylinder positioning. Our customers use these cylinders for accurate positioning and velocity control of their system.

These hydraulic cylinders with linear feedback are custom designed to meet the specific requirements of our customers’ applications.

These cylinders include electro-hydraulic, SMART, and linear position (LVDT). HDM offers numerous communication protocols including CANopen and Safety SIL2. They are ideal for applications in agricultural spraying and cultivation equipment; motion control; cut-to-length operations for manufacturing aluminum, steel, and non-metallic materials; aviation deicing; and more.

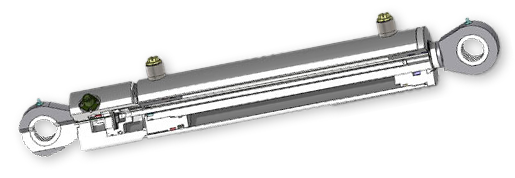

Linear feedback hydraulic cylinders are specialized hydraulic actuators that integrate position feedback sensors, typically linear position transducers, within the cylinder itself. These sensors provide real-time data on the piston rod’s position, allowing for precise control of movement and positioning. The feedback loop enables the system to adjust hydraulic pressure and flow automatically to achieve the desired movement or force, even compensating for variations in load or speed.

Linear feedback cylinders enhance accuracy, repeatability, and efficiency in processes like material handling, machine tool positioning, and large-scale construction operations. Additionally, they help reduce downtime and maintenance needs by providing diagnostic information that can indicate issues before they cause failure.

Linear hydraulic cylinders are used in a variety of markets that rely on precise control of motion and force, including:

Key Markets:

- Aerospace

- Agriculture

- Automotive

- Construction

- Oil & Gas

- Marine

Key Applications:

- Industrial Automation

- Machine Tools

- Aerospace Actuation Systems

- Construction Equipment

- Medical Equipment

- Hydraulic Presses

- Test Stands

Smooth Operation

Light Weight

Anodized Treated

Corrision Resistant

General Features & Specifications

Linear feedback hydraulic cylinders have numerous features that enhance their performance and versatility, including:

- Integrated Position Sensors such as linear variable differential transformers (LVDTs) that provide real-time feedback on the position of the piston, enabling precise control.

- High Pressure Rating because these cylinders are designed to operate at pressures, ranging from 2,000 to 5,000 psi, depending upon application requirements.

- Bore and Stroke Sizes commonly ranging from 1 to 12 inches and stroke lengths typically ranging from 6 inches to 90 inches to accommodate different applications.

- Durability and Corrosion Resistance due to being constructed from high-strength materials such as steel or aluminum, with surface treatments like hard chrome plating or anodizing to enhance corrosion resistance and durability in harsh environments.

- Compact Design and lightweight bodies to facilitate installation in tight spaces while delivering powerful performance.

- Control Options that can be integrated with various control systems, including proportional and servo valves which are ideal for advanced control systems and better responsiveness to changing load conditions.

Custom Linear Feedback Hydraulic Cylinders

Custom options for linear feedback hydraulic cylinders can include:

- Bore and Stroke Sizes

- Specialized Sensors

- Custom Mounts

- Seal Materials

- Surface Treatments

Hydraulic Cylinder Resources

Frequently Asked Questions

Have a question about Linear Feedback Hydraulic Cylinders? We are here to help.

What is a linear feedback hydraulic cylinder?

A linear feedback hydraulic cylinder is an actuator that combines hydraulic power with integrated position feedback sensors, allowing for precise control of the piston’s position and movement.

What are the advantages of using linear feedback cylinders?

They offer improved accuracy, repeatability, and responsiveness in applications, along with the ability to monitor performance and diagnose issues in real time.

What types of position sensors are used in these cylinders?

Common position sensors include linear variable differential transformers (LVDTs), potentiometers, and magneto strictive sensors, each providing different benefits for feedback accuracy.

What industries commonly use linear feedback hydraulic cylinders?

Industries such as aerospace, automotive manufacturing, construction, agriculture, and robotics frequently use these cylinders for various applications requiring precision control.

Can linear feedback cylinders operate under high pressure?

Can linear feedback cylinders operate under high pressure?

Yes, they are designed to operate at high pressures, typically ranging from 2,000 to 5,000 psi, depending on the specific design and application requirements.

How do I choose the right cylinder size for my application?

Consider factors such as the required stroke length, load capacity, available space, and mounting configurations to select the appropriate bore and stroke size for your needs.

Are linear feedback hydraulic cylinders suitable for outdoor use?

Yes, many linear feedback cylinders are designed with corrosion-resistant materials and coatings, making them suitable for outdoor environments. However, specific environmental considerations should be considered.

What maintenance do linear feedback cylinders require?

Regular inspections for leaks, wear on seals, and overall condition are recommended, along with periodic lubrication as specified by the manufacturer.

Can I retrofit my existing hydraulic system with linear feedback cylinders?

Yes, linear feedback cylinders can often be integrated into existing hydraulic systems, but compatibility with current controls and fittings should be evaluated.

What control options are available for linear feedback cylinders?

They can be paired with proportional and servo valves, allowing for advanced control strategies, including speed and position adjustments based on real-time feedback.

How do I troubleshoot issues with a linear feedback cylinder?

Start by checking for hydraulic fluid leaks, verify sensor functionality, and ensure proper electrical connections. Consulting the manufacturer's troubleshooting guide can provide additional insights.

What is the typical lifespan of a linear feedback hydraulic cylinder?

Lifespan can vary based on usage, maintenance, and environmental factors, but with proper care, they can last several years, often exceeding 5,000 to 10,000 operational cycles.

Can linear feedback cylinders be customized?

Yes, manufacturers often offer custom options, including specific bore sizes, stroke lengths, seal materials, and mounting configurations to meet unique application needs.

What are the common applications for linear feedback hydraulic cylinders?

They are commonly used in industrial automation, machine tools, aerospace actuation, construction equipment, and medical devices, among other applications requiring precise control.

How does the feedback mechanism improve performance?

The feedback mechanism allows for real-time adjustments to the hydraulic system, ensuring that the cylinder can respond to changes in load or speed, leading to enhanced accuracy and efficiency.

Contact Us

To learn more about how our innovative hydraulic cylinders are made with premium coatings and materials can deliver outstanding performance in highly corrosive environments, provide longer cylinders life, and decrease your maintenance costs, tell us who you are and briefly describe your application.

When you use HDM’s field-proven cylinders, you’re getting products and systems that are reliable, rugged and high-performance.