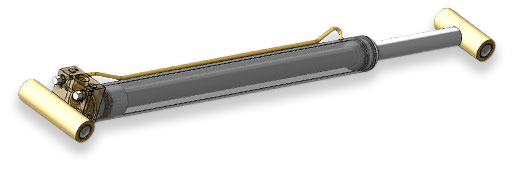

Cylinders with Integrated Valves

Integrated valves on hydraulic cylinders are valve components built directly into the cylinder body rather than being installed externally. These valves control the flow of hydraulic fluid within the cylinder, providing functions such as load holding, pressure relief, flow regulation, and load control. By embedding the valves into the cylinder, the need for additional plumbing, hoses, and external components is reduced, leading to a more compact and streamlined design. Types of integrated valves include counterbalance valves, pilot-operated check valves, sequencing valves, and thermal relief valves.

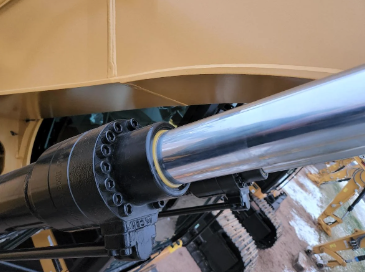

One of the primary benefits of integrated valves is improved efficiency and performance. Because the valves are located closer to the actuator (cylinder), response times are faster, and there is less risk of pressure loss or leakage that can occur with external connections.

Additionally, integrated valves can enhance safety by preventing cylinder drift or unexpected movement under load, as well as protecting against overpressure conditions.

Key Application:

- Aerospace

- Agriculture

- Construction

- Material Handling

- Mining

Key Markets:

- Brake Control

- Load Holding

- Motion Control

- Overload Protection

- Positioning & Steering

- Regenerative Circuits

Smooth Operation

Light Weight

Anodized Treated

Less Corrosive

than Steel

General Features & Specifications

Many cylinder designs have integrated valves, including counterbalance valves, pilot-operated check valves, sequencing valves, and thermal relief valves. HDM designs and manufactures hydraulic cylinders with integrated valves to meet the performance requirements of our customers' applications.

- Compact Design. Valves are built directly into the cylinder, reducing the need for external piping, fittings, and hoses, resulting in a more streamlined system.

- Pressure Ratings. Typically rated for high-pressure systems, integrated valves can withstand pressures ranging from 3,000 PSI to 5,000 PSI or more, depending on the application.

- Load Holding Capability. Integrated valves provide load-holding functions to prevent cylinder drift, ensuring safety and stability under varying loads.

- Quick Response Time. With valves located close to the actuator, these systems offer faster response times for precise control in demanding applications.

- Customizable Functions. Integrated valves can be tailored to specific needs, such as pressure relief, flow control, or load control, depending on the application’s requirements.

Custom Integrated Valves

Custom integrated valves in hydraulic cylinders are designed to meet specific application needs, offering tailored control functions such as load holding, pressure relief, or flow management. The valves’ most important function is their ability to enhance system efficiency, safety, and reliability by optimizing performance for unique operational requirements while minimizing the number of external components required.

Customizable features include:

- Load Holding and Locking Functions

- Pressure Relief Settings

- Flow Control and Metering

- Regenerative Circuits

- Check Valve Integration

- Multiple Valve Configurations

-2.png)

Hydraulic Cylinder Resources

To help understand double-acting hydraulic cylinders as deeply as you would like, we have created and compiled useful resources, including:

9 Questions to Ask Before

Specifying a Hydraulic Cylinder

Frequently Asked Questions

Have a question about integrated valves on hydraulic cylinders? We are here to help.

What are integrated valves in hydraulic cylinders?

Integrated valves are control components that are built directly into the hydraulic cylinder to manage fluid flow, pressure, and load control.

What are the benefits of using integrated valves?

Integrated valves reduce the need for external plumbing, enhance system response times, improve reliability, and help ensure safety through built-in load-holding and pressure relief functions.

What types of valves can be integrated into hydraulic cylinders?

Common types include check valves, pressure relief valves, load-holding valves, flow control valves, and directional control valves.

How do integrated valves improve system safety?

Integrated valves enhance safety by preventing cylinder drift, overpressure, and uncontrolled movements, ensuring stable operation under load.

Can integrated valves be customized for specific applications?

Yes, integrated valves can be custom-designed to meet specific operational needs, including custom pressure ratings, flow controls, and load-holding requirements.

What industries commonly use hydraulic cylinders with integrated valves?

Industries such as construction, agriculture, mining, material handling, and aerospace frequently use hydraulic cylinders with integrated valves for their machinery.

Do integrated valves reduce maintenance requirements?

Yes, by reducing the need for external hoses and fittings, integrated valves simplify the system and often reduce maintenance, leaks, and downtime.

Can integrated valves handle high-pressure applications?

Yes, integrated valves are designed to withstand high-pressure environments, often rated from 3,000 PSI to 5,000 PSI or more, depending on the application.

What is the lifespan of hydraulic cylinders with integrated valves?

The lifespan depends on the application and environment but can be enhanced due to fewer external components that are prone to wear and tear.

How does an integrated valve affect cylinder performance?

Integrated valves enhance performance by providing faster response times, better load control, and improved fluid efficiency, leading to smoother operation.

Can integrated valves be retrofitted into existing hydraulic cylinders?

Retrofitting integrated valves into existing cylinders is complex and may not be feasible; typically, they are incorporated during the cylinder’s design and manufacturing.

How do integrated valves affect overall system cost?

While integrated valves may increase initial cylinder costs, they reduce total system costs by minimizing external components, lowering installation and maintenance expenses, and improving system efficiency.

Contact Us

To learn more about how our innovative hydraulic cylinders are made with premium coatings and materials can deliver outstanding performance in highly corrosive environments, provide longer cylinders life, and decrease your maintenance costs, tell us who you are and briefly describe your application.

When you use HDM’s field-proven cylinders, you’re getting products and systems that are reliable, rugged and high-performance.