Hydraulic Locking Cylinders

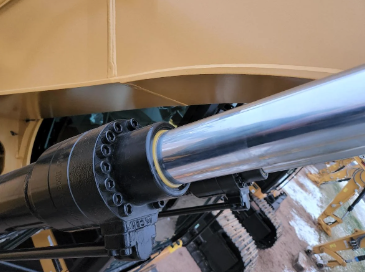

HDM designs and manufactures locking hydraulic cylinders for applications that require a hydraulic locking system.

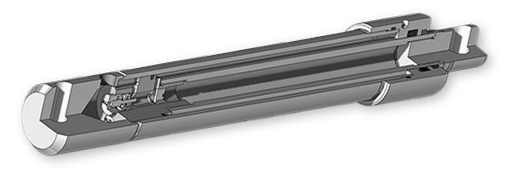

Our hydraulic locking features are uniquely integrated into the design of the cylinder and feature positive locking that creates secure connections between the piston and the cylinder.

Locking hydraulic cylinders are designed to hold a position securely when hydraulic pressure is lost or deliberately removed. They feature an integrated mechanical locking mechanism, which typically engages when the cylinder reaches its fully extended or retracted position, preventing the rod from moving even under heavy loads. This locking feature ensures stability and safety in applications where maintaining a fixed position is critical, such as in lifting equipment, construction machinery, and industrial presses.

Locking cylinders are used to provide additional safety and control, especially for applications in which a load must be held for an extended period without continuous hydraulic pressure. For example, in cranes, aerial platforms, or heavy equipment, locking hydraulic cylinders prevent accidental movement or collapse, which could otherwise lead to injury or damage. Hydraulic cylinders’ ability to lock in place also reduces wear on the hydraulic system, as the pump doesn't need to constantly maintain pressure to hold a load. Locking hydraulic cylinders are essential in applications that require a secure, fixed position for safety, reliability, and operational efficiency.

Key Markets:

- Aerospace & Defense

- Construction

- Energy & Utilities

- Industrial Machinery

- Material Handling

Key Applications:

- Cranes & Lifting Equipment

- Aerial Work Platforms

- Aircraft Landing Gear

- Industrial Presses

- Forklifts & Hoists

- Wind Turbines

Low Temp Operation

Corrosion Resistant

General Features & Specifications

The most significant features and specifications of locking hydraulic cylinders are:

- Integrated Locking Mechanism to hold the cylinder in a fixed position without continuous hydraulic pressure.

- High Load Capacity to support and maintain heavy loads in place securely, even under extreme conditions.

- Lock/Release Control for when the lock engages or disengages, ensuring precision and safety in operation.

- Durable Construction with high-strength materials and corrosion-resistant coatings to withstand the most demanding environments.

- Pressure & Stroke Ratings to meet the requirements of specific applications and ensure optimal performance.

- Safety Features such as fail-safe mechanisms and redundant locking systems to enhance safety in critical applications.

Custom Locking Hydraulic Cylinders

Custom locking hydraulic cylinders can be tailored offering enhanced performance and safety for meeting the unique demands of specific applications. Customization options allow for precise adjustments in design, such as load capacity, locking mechanisms, and material selection, ensuring the cylinder meets the operational and environmental requirements.

Custom options for locking hydraulic cylinders include:

- Locking Mechanism Types

- Load & Pressure Capacity

- Material Selection

- Custom Stroke Length

- Custom Bore Size

- Lock/Unlock Controls

- Mounting Configurations

Frequently Asked Questions

Have a question about Custom Locking Hydraulic Cylinders? We are here to help.

What types of locking mechanisms are available for custom locking hydraulic cylinders?

Common locking mechanisms include mechanical locks like pin or pawl systems and hydraulic locks that engage automatically when pressure is lost or removed. The specific mechanism can be tailored to the application.

How do I determine the correct load and pressure capacity for a custom locking cylinder?

Load and pressure capacity depend on the specific operational requirements, including the weight of the load, the amount of force needed, and the hydraulic system's pressure. Consultation with a hydraulic engineer and a thorough understanding of the application's demands are essential.

What materials can be used to construct custom locking hydraulic cylinders for extreme environments?

Materials like stainless steel, hardened steel, and special alloys can be used for enhanced durability and corrosion resistance in extreme environments, such as high temperatures or corrosive conditions.

Can custom locking hydraulic cylinders be designed for remote or automated control?

Yes, custom locking cylinders can be outfitted with electronic or hydraulic systems that allow for remote or automated engagement and disengagement of the locking mechanism, providing enhanced control in complex applications.

What are the options for customizing stroke length and bore size in locking cylinders?

Stroke length and bore size can be tailored to the specific force and distance requirements of the application, ensuring the cylinder delivers the appropriate performance and meets spatial constraints.

How does the locking mechanism engage and disengage in custom designs?

The locking mechanism can be designed to engage automatically when the cylinder reaches its extended or retracted position, or it can be controlled manually or remotely, depending on the application’s needs.

What industries or applications benefit most from custom locking hydraulic cylinders?

Industries like construction, aerospace, defense, manufacturing, and energy benefit from custom locking hydraulic cylinders, particularly in applications that require maintaining a fixed position under load, such as in lifting equipment, presses, or landing gear.

Can custom locking hydraulic cylinders be made to meet specific safety standards or certifications?

Yes, custom cylinders can be designed to meet industry-specific safety standards or certifications, such as ISO, ANSI, or OSHA regulations, ensuring compliance with safety and performance requirements.

What maintenance is required for custom locking hydraulic cylinders, and how does it differ from standard cylinders?

Maintenance typically includes regular inspection of the locking mechanism, seals, and hydraulic lines. The locking feature may require additional checks to ensure proper engagement and disengagement, especially in high-load or safety-critical applications.

How can I choose the right mounting configuration for my custom locking hydraulic cylinder?

The mounting configuration should be selected based on the equipment layout and operational demands. Common options include clevis, trunnion, flange, or pivot mounts, and the choice depends on factors like load direction, available space, and installation preferences. Consulting with a supplier or engineer can help determine the best option for your setup.

Contact Us

To learn more about how our innovative hydraulic cylinders are made with premium coatings and materials can deliver outstanding performance in highly corrosive environments, provide longer cylinders life, and decrease your maintenance costs, tell us who you are and briefly describe your application.

When you use HDM’s field-proven cylinders, you’re getting products and systems that are reliable, rugged and high-performance.